Trusted RF Shielded Test Enclosure Rochester for Advanced Electronic Devices Safety And Security

Trusted RF Shielded Test Enclosure Rochester for Advanced Electronic Devices Safety And Security

Blog Article

Optimizing Examining Precision With Shielded Test Enclosures in Electronic Development Procedures

Protected examination enclosures have actually emerged as a crucial device in enhancing the accuracy of screening procedures for electronic components and tools. The use of shielded test enclosures expands past simple insulation, providing a myriad of advantages that add to the overall quality and effectiveness of screening end results.

Significance of Protected Examination Units

The usage of shielded examination enclosures is critical in making certain trusted and precise digital development processes. Protected units provide a regulated screening atmosphere by preventing electromagnetic interference (EMI) from external sources that can endanger the stability of digital screening procedures. This is particularly crucial in delicate electronic measurements where also the slightest disturbance can lead to wrong results. By consisting of the electromagnetic signals within the unit, secured examination units assist maintain the uniformity and repeatability of test outcomes, inevitably boosting the total high quality of digital advancement processes.

Moreover, protected examination rooms add to conference governing criteria and compliance requirements in the electronic devices industry. These enclosures help in producing a shielded area that lessens the threat of emissions that might hinder other electronic devices or communication systems. This not only ensures the reliability of the gadgets being tested but also avoids any kind of potential disruptions to surrounding devices. In essence, the value of protected test rooms exists in their ability to secure the accuracy and reliability of digital advancement procedures via the development of a controlled and interference-free testing setting.

Kinds Of Secured Test Enclosures

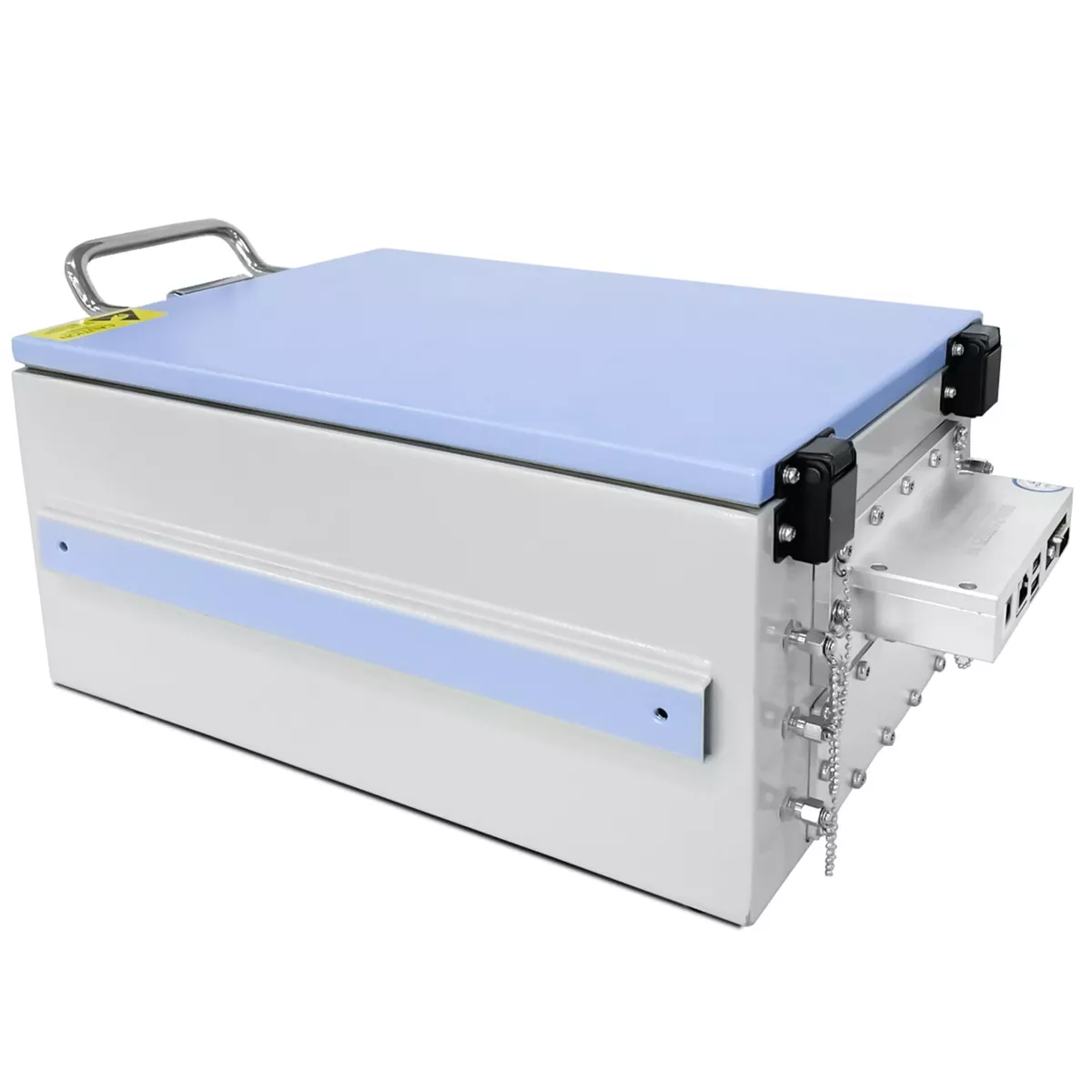

Various setups of shielded test rooms satisfy diverse screening demands and specifications in electronic growth processes. One usual type is the benchtop protected test enclosure, which is small and ideal for checking tiny digital devices or components. These units offer a secured atmosphere that prevents external disturbance during testing, ensuring precise results. An additional kind is the rack-mounted secured test room, which is designed to suit typical devices shelfs. This type of unit is suitable for larger screening arrangements where several devices require to be examined simultaneously. Furthermore, mobile secured examination units supply adaptability for on-site testing or when movement is called for. These rooms are easy and lightweight to move, making them perfect for area testing or troubleshooting electronic systems (rf test enclosure rochester). On the whole, the option of secured examination room depends on the specific screening needs, the size of the gadgets being evaluated, and the level of mobility called for in the digital development process.

Benefits of Using Protected Units

Enhancing electro-magnetic compatibility and making certain trusted examination results, protected enclosures play a vital duty in keeping the honesty of digital growth procedures. One of the vital benefits of making use of secured enclosures is their ability to mitigate electromagnetic disturbance (EMI) from exterior resources. By providing a controlled atmosphere with very little exterior disturbance, shielded units allow exact screening of digital gadgets without the danger of incorrect results triggered by visit here unwanted electro-magnetic signals.

Furthermore, secured enclosures use a high degree of safety and security by stopping delicate details from dripping out and unauthorized signals from going into the screening environment. This feature is specifically crucial when screening proprietary or private digital parts that call for a safe and secure screening atmosphere.

In addition, shielded rooms help in complying with governing requirements and accreditations by supplying a regulated screening environment that fulfills the needed electromagnetic compatibility (EMC) guidelines. This makes certain that the electronic tools being checked will certainly meet the needed sector standards for electro-magnetic emissions and immunity, causing smoother certification procedures and quicker time-to-market for products.

Considerations for Secured Enclosure Choice

In the procedure of selecting protected units for digital development, cautious factor to consider of ecological elements and specific requirements is extremely important. The very first factor to consider when choosing a protected unit look at more info is the material made use of for its building and construction. Conductive materials such as steel or aluminum are commonly preferred for their protecting effectiveness. Furthermore, the dimension of the unit have to be adequate to suit the electronic elements being tested while allowing for proper ventilation and wire administration.

An additional important variable to think about is the level of securing required for the testing environment. High-frequency applications might demand enclosures with premium electromagnetic disturbance (EMI) shielding capabilities to stop signal disturbance and make sure accurate test results. Moreover, the accessibility functions of the enclosure, such as doors, panels, and ports, should align with the screening needs to promote practical accessibility to the tools under examination.

Last but not least, the transportability and scalability of the secured unit ought to be reviewed to ensure flexibility in suiting future screening needs and potential reconfigurations. By very carefully analyzing these considerations, digital advancement processes can maximize screening accuracy and performance with the suitable protected enclosure choice.

Combination of Shielded Enclosures in Testing

The smooth assimilation of protected enclosures right into screening treatments is essential for ensuring reputable and exact electronic advancement procedures. Shielded units play an essential function in lessening external interference during screening, therefore improving the accuracy of outcomes. When integrating secured units into screening environments, learn the facts here now it is necessary to consider elements such as the dimension of the unit, the kind of securing product made use of, and the particular testing needs of the electronic components being assessed.

One key element of integrating secured enclosures into screening is guaranteeing correct connectivity within the enclosure. This includes developing safe and secure links for source of power, information transfer, and surveillance devices to properly perform tests while maintaining the shielding efficiency of the unit. Furthermore, carrying out proper ventilation and cooling systems within the enclosure is critical to avoid getting too hot of electronic components during testing procedures.

Conclusion

Finally, the usage of secured examination units in digital growth procedures is important for making best use of testing accuracy. Various kinds of shielded rooms use various benefits, and cautious factor to consider needs to be provided to picking the most appropriate one for details testing requirements. Incorporating secured enclosures into the screening procedure can considerably enhance the integrity and effectiveness of digital screening procedures.

Protected units provide a regulated screening setting by avoiding electro-magnetic interference (EMI) from exterior sources that can endanger the honesty of electronic testing treatments - faraday cage rochester. By containing the electromagnetic signals within the room, secured test rooms help keep the consistency and repeatability of examination outcomes, inevitably enhancing the overall top quality of digital development procedures

When incorporating protected units right into screening atmospheres, it is crucial to think about variables such as the size of the unit, the kind of protecting material used, and the certain testing requirements of the electronic parts being reviewed.

One key element of integrating shielded enclosures right into screening is making certain correct connection within the room. Incorporating shielded units right into the screening process can dramatically boost the dependability and performance of digital screening procedures.

Report this page